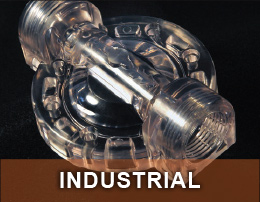

High-quality custom plastic parts in any volume

Low-volume injection molding is as important to us as our higher volume work. We give every project the same high level of care and attention regardless of quantity.

Our skilled operators use state-of-the-art presses to deliver high-quality engineered plastic parts in any quantity. We are adept at manual inserts and hand loads for low-volume molding. Our robotic systems speed insert loading and finished part extraction when appropriate. We are continuously updating and expanding our injection molding facility near Rochester, NY, and added six new machines in 2012-2013.

Exceptional value and scope

- Exceptional value in mold creation: We do mold design, building and maintenance right here in the USA… and leverage decade-long partnerships with carefully chosen mold makers offshore.

- The right equipment: Our 17 injection molding machines include late-model Arburg, Sandretto, and Van Dorn presses with 40 to 425 tons force and up to 44-ounce shot size.

- Process control: Experienced technicians (averaging 30+ years in the business) and documented process control deliver consistent results. We can meet demanding Cpk requirements.

- Hand loads: Get complex geometries at reasonable cost, even in low volume.

- Over-molded inserts: We mold metal or plastic elements into your part to meet the functional requirements of your product.

Materials

We have extensive experience with virtually all commodity plastics and engineered resins. Let us help you choose the right material for your job! We routinely mold parts using:

- Delrin (POM)

- Isoplast

- Kynar (PVDF)

- Noryl

- Filled and Unfilled Nylon

- Polycarbonate

- Polyester

- Propylene

- PVC

- Ryton

- SAN

- Tefzel (ETFE)

- Ultem (PEI)

- Ultrason (PSU and PESU)

- Versaflex

- And many more

Learn more

- How our tooling keeps costs down and quality up.

- How our engineering services help you solve design problems and optimize manufacturability.

- How can we help you buy injection-molded parts? Contact us today!