Custom plastic parts to complete finished products

CY Plastics excels at injection molding and blow molding of engineered components for industrial, medical and commercial products.

We offer exceptional quality and value in mold production, combining well-established offshore tooling partnerships with in-house expertise in tool design, production and maintenance.

We provide high-quality, low- to mid-volume molded plastic part production near Rochester, NY. Our skilled technicians employ modern equipment and have expertise with a wide range of specialty plastics.

With comprehensive finishing, assembly and inventory services, we deliver a complete finished product to our customers. Our expert guidance and personal attention at every step of the process ensure high customer satisfaction.

Background and history

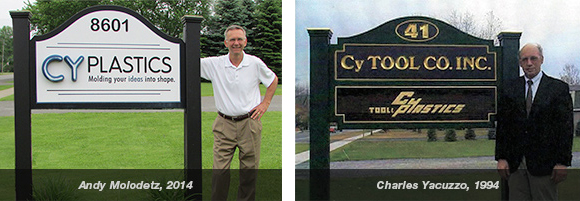

CY Plastics has more than 30 years of experience in plastics molding. We started in 1978 as CY Tool Company, focused on tooling for injection molding. By 1980 we were providing complete injection molding services. We moved into our current 25,000-square-foot facility in 1995 and added blow molding services in 2002.

In 2006 Andy Molodetz purchased the company from founder Charles Yacuzzo. A native of western New York and a graduate of Syracuse University, Andy brings more than 30 years of experience in sales and manufacturing of engineered equipment with companies including Goulds Pumps, IDEX, and Gardner Denver. He continues the commitment to maintain and grow CY Plastics manufacturing in upstate New York.

Today we continue to update and expand our production capabilities, adding six new molding machines and two crane systems in 2012-2013. We opened an adjacent 12,500-square-foot warehouse in 2012 to support the growing demand for managed inventory programs.

CY Plastics customers are located from Utica to Buffalo and throughout the United States. They include Tyco International, Konica-Minolta, IDEX, Welch Allyn, Electrochem and Bausch + Lomb.